These features made it one of the most sought after and most powerful muscle cars of their era. The total 1970 redesign was based on the E-Body, essentially a wider and shorter version of Chrysler's B platform that was used for rear-wheel drive passenger cars. Plymouth ditched its original fastback roots by transforming the vehicle into a two-door coupé and also creating a convertible version. The masterpiece of this car was the 426 Hemi V8 engine equipped with hemispherical chambers (hence the abbreviation Hemi), with a displacement of 7 litres capable of unleashing 425 HP and making it record a time of 5.8 seconds in zero to 100 km/h and push it to a maximum speed of about 250 km/h.

The new “Hemi Cuda” was designed by a young designer named John Herlitz, who was only 27 at the time. The revamped but still large car was slightly downsized while still remaining true to muscle car proportions with a long hood and engine compartment, necessary to accommodate the large V8 engine, and a short trunk. The Hemi Cuda became a huge success for Chrysler by doubling the sales from just under 28,000 a year to a whopping 50,617 total cars, 652 of which were Hemi Cuda coupés and 14 were very rare convertibles. The sparse equipment, which did not include air conditioning and power steering, for example, clearly hinted at its performance intentions.

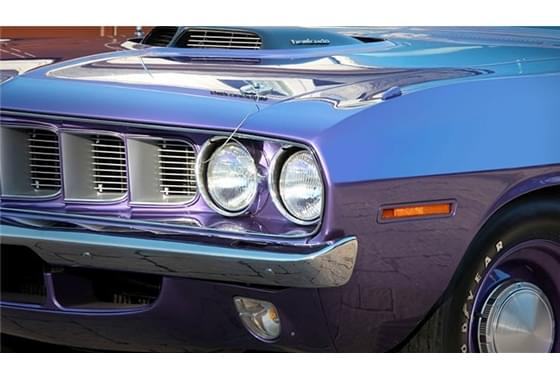

In 1971 the model had a small restyling that made the design even more menacing thanks to the quadruple circular headlights, the simulated side air intakes that aesthetically recalled the gills of the Barracuda and the matt black-tinted shaker hood to avoid glare when driving. At the last Mecum auction in Pebble Beach, a Hemi Cuda Convertible model sold for around $ 3 million, a record figure for an American car of that type.

In all body shops, even those dedicated to antique cars, an appropriate extraction and filtration system for sanding dust is necessary in order to avoid its dispersion in the working environment - to safeguard both the work already carried out and workers’ health.

This month WORKY would like to talk about a simple yet professional solution. the DMOB2!

The DMOB2 unit is equipped with 2 1000W rated motors, single power adjustment selector to use both motors in equal measure, 2 electrical sockets, 2 quick couplings for compressed air supply, cellulose bag filter and post filtration unit in case of accidental breakage of the dust bag. The DMOB2 is equipped with an automatic start controlled by the tool.

The DMOB2 is also part of the DKIT kits with 3 or 6 metre DARM wall arm, to bring the multifunction control unit - with which the arm itself ends - in the desired position. Pneumatic connections and electrical sockets as well as sanding dust extraction can be connected from the multifunction control unit.

Whether you have a large or small body shop, we are available to discuss the solution that best suits your needs with you!