Exhaust gas extraction: the best way to expel gases from the workshop

Exhaust gases are among the most dangerous substances for our health; both when emitted by gasoline engines, both when emitted by diesel engines, the exhaust gases are responsible for common diseases: stroke, respiratory and cardiovascular disorders, asthma, and lung cancer.

What are these gases made of? Why are they harmful?

Exhaust gas: how are they produced?

The exhaust gases are the product of gasoline or diesel oil - that is, liquid hydrocarbons - combustion together with air – i.e. oxygen and nitrogen; subjected to high temperature, this mixture produces two effects: on the one hand, it frees energy indispensable to operate the engine, on the other, it produces waste substances that are, precisely, the exhaust gases.

Exhaust gases contain many toxic elements

These gases are made of a set of elements:

- Carbon dioxide, non-toxic

- Carbon monoxide, toxic if present in quantities greater than 2% in the air breathed

- Unburned hydrocarbons, irritating and carcinogenic

- Nitrogen oxides, irritants

- Oxygen

- Nitrogen

- Water vapour.

Carbon monoxide (CO), unburnt hydrocarbons (HC), nitrogen oxides (NOx) and in some cases sulphur oxides (SOx) are mainly responsible for the diseases we have been talking about before.

The importance of gas extraction systems

In mechanical workshops, maintenance interventions often require keeping the vehicle on: the engine is running and the combustion process in progress; from the muffler exhaust gas escapes and mechanics are in very close contact with it.

In order not to seriously damage mechanics’ health, it is essential to eliminate those exhaust gas: extraction is the only way.

Well, filtration may be the first solution you think about; however, exhaust gases toxic particles are so fine and impalpable that they escape any attempt at filtering. In order to neutralize the gas toxic action, you need to remove the product before releasing it into the air.

We need specific equipments

The only way to eliminate the exhaust gases is to take them directly from the vehicle's muffler and transport them outside of the workshop, without dispersing them along the way.

For this purpose, experts have designed and built specific exhaust gas extraction systems for workshop: systems consisting of nozzles, flexible hoses and powerful fans that capture the gases as soon as they are emitted, and safely expel them outside the building.

Gas extraction systems are a necessary measure, as also established by work safety regulations: in all the enclosed spaces where there is emission of exhaust gas, it is mandatory to install gas extraction systems, in order to preserve workers’ health.

WORKY systems for exhaust gas extraction

WORKY specializes in the production of exhaust gas extraction equipment.

Our gas extractions systems are of 4 types:

- Fixed

- Sliding

- Stand-alone

- Underfloor

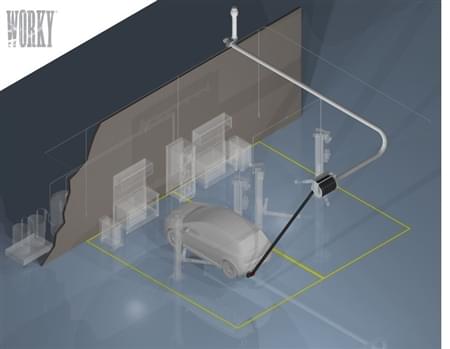

A. Fixed systems

The fixed systems are not installed on wheels, and require a complete, permanent installation.

The fixed systems are not installed on wheels, and require a complete, permanent installation.

A fixed extraction system consists of an assembly of nozzle, tube and support fixed to the wall; the suction unit is fixed in a permanent position above the workstation.

A galvanized pipe is required to expel the exhaust gases directly outside the workshop.

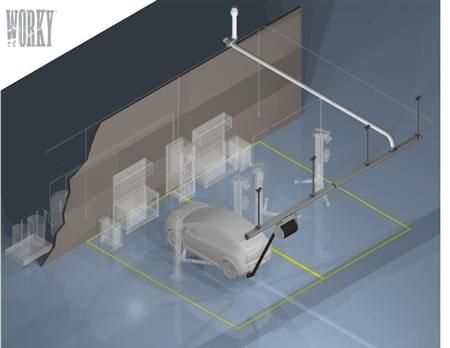

B. Sliding systems

The sliding systems differ from the previous ones because the tube-nozzle-reel assembly is movable, that is, it can be shifted from one point to another, thanks to a rail that acts as a channel for the sliding elements.

The sliding systems differ from the previous ones because the tube-nozzle-reel assembly is movable, that is, it can be shifted from one point to another, thanks to a rail that acts as a channel for the sliding elements.

The advantage of the sliding system is that it allows covering many workstations, even when they are located far apart from one another; moreover, being anchored to the rail, the sliding elements do not encumber neither hinder mechanics’ movements.

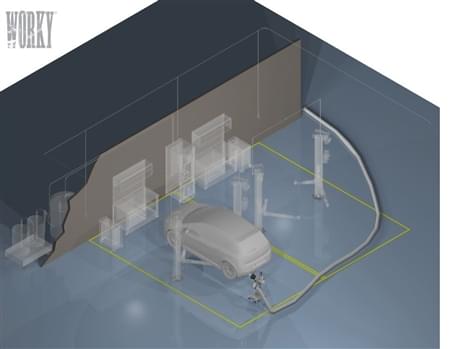

C. Stand-alone systems

The stand-alone systems for exhaust gas extraction are the preferred solution by small workshops: they do not require installation, being instead composed of a portable system, easily transportable from one area to another simply by moving it on wheels.

The stand-alone systems for exhaust gas extraction are the preferred solution by small workshops: they do not require installation, being instead composed of a portable system, easily transportable from one area to another simply by moving it on wheels.

Stand-alone systems must also be equipped with an expulsion hose, but no declaration of emissions into the atmosphere or roof chimney installation is required.

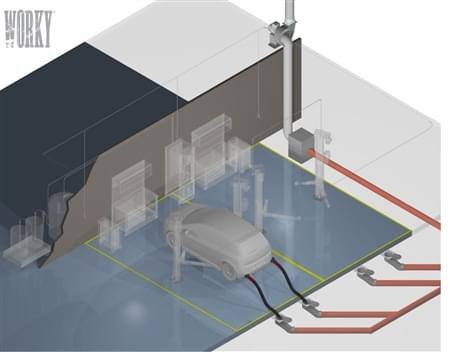

D. Underfloor systems

We come to the last solution for aspiration, the most articulate; the underfloor systems, as the name implies, develop below the floor: it is therefore clear that they must be built in conjunction with the construction of the workshop, or with its restructuring.

We come to the last solution for aspiration, the most articulate; the underfloor systems, as the name implies, develop below the floor: it is therefore clear that they must be built in conjunction with the construction of the workshop, or with its restructuring.

Underfloor systems can be of two types:

1. Pipes placed underground and extracted according to need;

2. Central suction unit and hose-holding bends grafted if necessary directly on the floor trap.

The entire system, once built, is almost invisible ; it is cheaper than other solutions: for this reason it is in great demand in the workshops where the need exhaust gas extraction is lower than in other service centres.

To recap:

- If your need of exhaust gas extraction is low and you have the possibility to intervene on the workshop structure, we recommend an UNDERFLOOR extraction system.

- If you need to extract exhaust gases very often, but your workshop has small dimensions or a few workstations, you can choose a FIXED system.

- If you need to extract exhaust gases very often and the workshop is large, with many workstations located next to each other, we recommend a SLIDING system.

- If you have only temporary exhaust gas extraction needs and do not want to deal with a permanent installation, you can rely on a STAND-ALONE system.

Do you have any doubts? Do you want more information on our exhaust gas extraction systems? Do you want to make an appointment?

For any reason, contact us without obligation.

Exhaust gases are among the most dangerous substances for our health; both when emitted by gasoline engines, both when emitted by diesel engines, the exhaust gases are responsible for common diseases: stroke, respiratory and cardiovascular disorders, asthma, and lung cancer.

What are these gases made of? Why are they harmful?

Exhaust gas: how are they produced?

The exhaust gases are the product of gasoline or diesel oil - that is, liquid hydrocarbons - combustion together with air – i.e. oxygen and nitrogen; subjected to high temperature, this mixture produces two effects: on the one hand, it frees energy indispensable to operate the engine, on the other, it produces waste substances that are, precisely, the exhaust gases.

Exhaust gases contain many toxic elements

These gases are made of a set of elements:

- Carbon dioxide, non-toxic

- Carbon monoxide, toxic if present in quantities greater than 2% in the air breathed

- Unburned hydrocarbons, irritating and carcinogenic

- Nitrogen oxides, irritants

- Oxygen

- Nitrogen

- Water vapour.

Carbon monoxide (CO), unburnt hydrocarbons (HC), nitrogen oxides (NOx) and in some cases sulphur oxides (SOx) are mainly responsible for the diseases we have been talking about before.

The importance of gas extraction systems

In mechanical workshops, maintenance interventions often require keeping the vehicle on: the engine is running and the combustion process in progress; from the muffler exhaust gas escapes and mechanics are in very close contact with it.

In order not to seriously damage mechanics’ health, it is essential to eliminate those exhaust gas: extraction is the only way.

Well, filtration may be the first solution you think about; however, exhaust gases toxic particles are so fine and impalpable that they escape any attempt at filtering. In order to neutralize the gas toxic action, you need to remove the product before releasing it into the air.

We need specific equipments

The only way to eliminate the exhaust gases is to take them directly from the vehicle's muffler and transport them outside of the workshop, without dispersing them along the way.

For this purpose, experts have designed and built specific exhaust gas extraction systems for workshop: systems consisting of nozzles, flexible hoses and powerful fans that capture the gases as soon as they are emitted, and safely expel them outside the building.

Gas extraction systems are a necessary measure, as also established by work safety regulations: in all the enclosed spaces where there is emission of exhaust gas, it is mandatory to install gas extraction systems, in order to preserve workers’ health.

WORKY systems for exhaust gas extraction

WORKY specializes in the production of exhaust gas extraction equipment.

Our gas extractions systems are of 4 types:

- Fixed

- Sliding

- Stand-alone

- Underfloor

A. Fixed systems

The fixed systems are not installed on wheels, and require a complete, permanent installation.

A fixed extraction system consists of an assembly of nozzle, tube and support fixed to the wall; the suction unit is fixed in a permanent position above the workstation.

A galvanized pipe is required to expel the exhaust gases directly outside the workshop.

B. Sliding systems

The sliding systems differ from the previous ones because the tube-nozzle-reel assembly is movable, that is, it can be shifted from one point to another, thanks to a rail that acts as a channel for the sliding elements.

The advantage of the sliding system is that it allows covering many workstations, even when they are located far apart from one another; moreover, being anchored to the rail, the sliding elements do not encumber neither hinder mechanics’ movements.

C. Stand-alone systems

The stand-alone systems for exhaust gas extraction are the preferred solution by small workshops: they do not require installation, being instead composed of a portable system, easily transportable from one area to another simply by moving it on wheels.

Stand-alone systems must also be equipped with an expulsion hose, but no declaration of emissions into the atmosphere or roof chimney installation is required.

D. Underfloor systems

We come to the last solution for aspiration, the most articulate; the underfloor systems, as the name implies, develop below the floor: it is therefore clear that they must be built in conjunction with the construction of the workshop, or with its restructuring.

Underfloor systems can be of two types:

1. Pipes placed underground and extracted according to need;

2. Central suction unit and hose-holding bends grafted if necessary directly on the floor trap.

The entire system, once built, is almost invisible ; it is cheaper than other solutions: for this reason it is in great demand in the workshops where the need exhaust gas extraction is lower than in other service centres.

To recap:

- If your need of exhaust gas extraction is low and you have the possibility to intervene on the workshop structure, we recommend an UNDERFLOOR extraction system.

- If you need to extract exhaust gases very often, but your workshop has small dimensions or a few workstations, you can choose a FIXED system.

- If you need to extract exhaust gases very often and the workshop is large, with many workstations located next to each other, we recommend a SLIDING system.

- If you have only temporary exhaust gas extraction needs and do not want to deal with a permanent installation, you can rely on a STAND-ALONE system.

Do you have any doubts? Do you want more information on our exhaust gas extraction systems? Do you want to make an appointment?

For any reason, contact us without obligation.