It is in WORKY DNA to release new installations all the time, now we would like to tell you about this particular case of "excellence".

We are in the Audi world, a brand standing for high-quality, performance and design. The car dealer would like to create a service center of "excellence" in Töveks, and turned to the WORKY dealer, confident that he would understand and satisfy his requests. During the meeting organised to further comprehend the customer's requirements and wishes, the AUDI aftersales manager, immediately raised an issue: he was overwhelmed by all the different types of exhaust pipes, which on one side, were enriching the car design, but on the other, were forcing the technicians to change nozzles very often, which would result in wasting precious time. Moreover, every year it was necessary to invest in new adaptors to keep up with the new models.

WORKY'S project manager, together with the dealer, presented a solution to this problem: the universal touchless GTL arm.

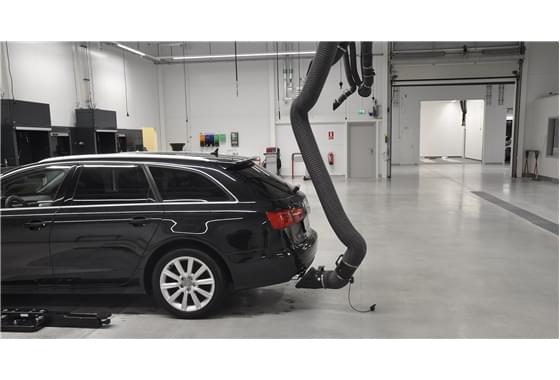

The GTL is a self-supporting arm, designed by the WORKY team for exhaust extraction, without ever touching the car. The arm can be easily positioned by the car bumper and it can extract all of the gases out of the work bay, no matter what shape or location of the pipe. Moreover, since it does not have to touch the car, it prevents the risk of scratches or damages.

The customer was enthusiastic; however, he came up with a new question: what would happen when cars of different lengths were placed on the lifts? In fact, the workshop could service A1 cars as well as Q7, and the distance between rail and bumper would change considerably.

Thanks to its extreme flexibility, the universal GTL arm has an extension of 2,5m from the rail (datasheet), making it absolutely unique.

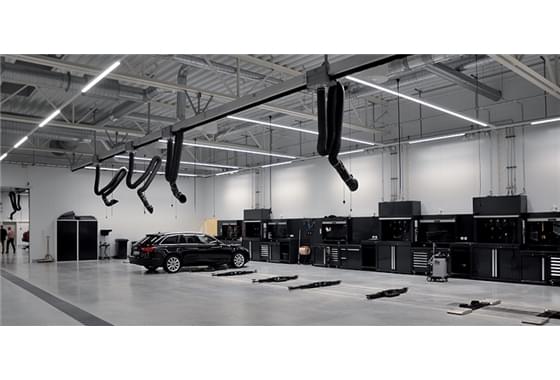

The aftersales manager resolved all doubts and the GTL touchless were then installed in both the workshop and the body shop.

The system was so easy to use we convinced the customer to install the same system but for welding fumes, this time he chose the mobile SBF-160 mobile arms.

The result was a functional service center and a user-friendly work environment.