Turbines

Extracting the sanding dust produced during vehicle sanding processes is essential to maintain the efficiency of the bodywork and to protect the health and safety of workers.

Extraction turbines, especially, are an element that should not be underestimated.

Why extraction turbines are essential in bodyshops

Sanding is the process that is used in bodyshops to smooth vehicle bodywork, making it flat and without imperfections, ensuring that it has a good base for a perfect paint job.

During this process, however, a lot of dust is produced which, besides being potentially hazardous to the health of technicians, can settle on the bodywork and affect the quality of the final work.

This becomes a serious detriment to bodyshop productivity. Having to repeat a job means wasting time and resources, as well as not being able to address time to other activities. As a result, fewer jobs will be completed at the end of the day and consequently the bodyshop's productivity will be lower.

The solution is to install a modern dust extraction system

A modern dust extractor eliminates toxic substances before they are dispersed into the environment, removing them directly from the orbital sander, i.e. from the production source. This ensures that the working area remains clean and healthy.

The turbines are one of the components to pay most attention to when choosing the most suitable extraction system, because it is the turbine's extraction capacity that determines the healthiness and cleanliness of the bodywork.

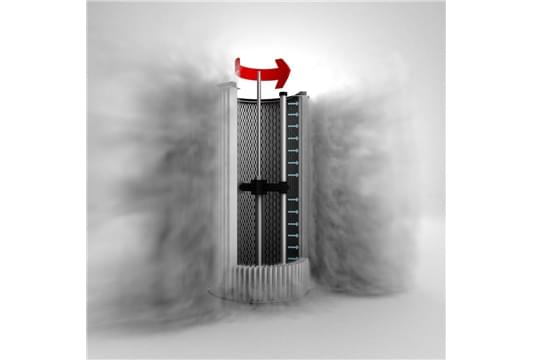

The turbines of WORKY's DT series have been designed to extract and filter the sanding dust specifically designed for bodywork dust.

The process starts with the orbital polishers with a cowling for extracting the dust produced these are connected to the hoses by units or arms.

The extracting capacity of the turbine enables the dust to be removed, extracted by the hoses as far as its high-efficiency filter, which retains 99.9% of the dust. The virtually dust-free air is expelled from the vertical exhaust and returned to the premises or atmosphere. The self-cleaning filter with rotor-jet system are made of non-stick Teflon; the extreme quietness and efficiency makes it the best way of extracting dust with a centralized system that is second to none.

The WORKY turbines cover a range from 3 to 20 CV and have been designed for fine and impalpable dust like that produced when working on bodywork.

In addition to the turbines, the other elements to pay attention to are:

Extracting arms, usually made of aluminium to be light, manoeuvrable and corrosion-resistant; with different lengths, to be chosen according to the needs of the bodyshop and the distance between the different working areas.

Service units, which supply electrical and pneumatic power to the working areas. They can be wall-mounted (suspended by a tube containing all the power supplies) or wall-mounted (consisting of an equipped front panel, with all connections at the rear).

Ducts, which can be made of aluminium (an inert material that prevents sucked dust from accumulating inside the pipe) or polyurethane (ideal for installations requiring very flexible pipes).

Fixed or mobile dust extractor?

The choice of the type of system depends on the needs of the bodyshop, the size of the working area and the frequency of use.

Fixed systems are recommended in medium to large bodyshops where sanding activity is very frequent and continuous.

Mobile systems and trolley mounted units, on the other hand, being very practical and manoeuvrable, are perfect for locations where sanding takes place less frequently and where the areas dedicated to this activity are far apart. Mobile systems can in fact be moved effortlessly.

It is important to rely on a supplier who can assess the needs of the facility and advise and implement the most suitable dust extraction system for individual needs, tailored to each customer.

If you need advice on different types of extraction turbines or dust extraction systems for your bodyshop, book a consultation with WORKY technicians!

You can clarify your doubts and find the best solution for your employees!

Catalogue turbines

Extraction turbine with 3 HP side channel blower and cartridge filter with automatic cleaning sys...

See details

Extraction turbine with 4 HP side channel blower and cartridge filter with automatic cleaning sys...

See details

Extraction turbine with 5.5 HP side channel blower and cartridge filter with automatic cleaning s...

See details

Extraction turbine with 7.5 HP side channel blower and cartridge filter with automatic cleaning s...

See details

Double extraction turbine with two 5.5 HP side channel blowers and cartridge filter with automati...

See details

Double extraction turbine with two 7.5 HP side channel blowers and cartridge filter with automati...

See detailsExtraction turbine with 10 HP side channel blower, inverter and cartridge filter with automatic c...

See details

Prefilter for separating the coarser grains during the vehicle cleaning process. Only the finer d...

See details

ATEX prefilter for separating the coarser grains during the vehicle cleaning process. Only the fi...

See details

ATEX extraction turbine with 4 HP side channel blower and cartridge filter with automatic cleanin...

See details

ATEX extraction turbine with 5.5 HP side channel blower and cartridge filter with automatic clean...

See details

ATEX extraction turbine with 7.5 HP side channel blower and cartridge filter with automatic clean...

See details