Out of all our welding fume extraction systems, the complete kits are among the most appreciated by our customers. The reason lies in their completeness, which translates into practicality, the perfect combination of efficiency and simplicity.

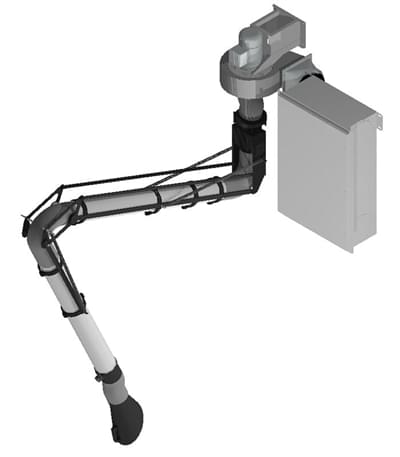

SPARK line kits are wall mount kits, complete with all parts:

- wall-mounted electric fan and filter

- hinged arm.

SPARK kits: extraction power and filtering efficiency

In the complete kits, the extraction power is provided by the wall-mounted electric fan, while the possibility of filtering the air, and returning it deodorized into the environment, is guaranteed by the series of filters.

In detail, the air passes through the self-supporting arm with external pantograph structure, return springs and adjustable clutches, and is then filtered thanks to the SFTC filter made of sturdy steel sheet metal, with filtration efficiency up to 95%. The extraction arms belong to the SB series, specific for the extraction of welding fume from the work area: they are self-supporting and have at least 3 joints, in order to assume any configuration and reach even the most difficult points.

Thanks to active carbon, the air is also deodorized before being reintroduced into the environment (wherever possible).

The importance of filters

The 95% filtration efficiency is guaranteed by the SFTC filter module, made up of:

- 1 metallic fabric pre-filtering stage (spark-extinguisher)

- 1 synthetic filter, which blocks coarser particles

- 1 high efficiency filter cell

- 1 active carbon stage.

The fume exhaust flue

Have fume extraction systems in workplaces where welding operations are carried out is necessary and mandatory, as established by the Consolidated Law on workplace safety and by a series of specific standards that regulate welding operations.

Although extraction is mandatory, filtering fumes is not always mandatory:

- if it is possible to return the filtered fumes to the environment, the SPARK kits are sufficient

- if it is not possible, then the fumes must be ducted via a special flue connected to the kit.

The same applies to those work environments where regional regulations prevent the re-emission of fumes. In all cases, WORKY will provide you with the simplest and most efficient solution.

When and where do SPARK kits offer maximum performance?

SPARK kits are the most functional and versatile solution, and are particularly suitable in all situations where welding is carried out in a defined area within the arm's working range (which can also reach 5 m length, depending on the kit chosen).

In this case, in fact, investing in a wall mounted system allows you to leave technicians greater freedom of movement within the work area.

SPARK and SPARK 10: how do they differ?

The complete kit range includes two models: SPARK and SPARK 10. Their parts and extraction power are the same, while the difference lies in the amount of active carbon contained: in SPARK, we are talking about 5 kg, in SPARK10, 10 kg.