How is an exhaust gas extraction system designed from scratch for a new workshop? The WORKY designers explain it to you, step by step.

Workshop exhaust gas extraction systems designed by WORKY designers take place through 8 fundamental steps, to which, depending on the specific case, others may be added.

These 8 steps include:

- Customer interview

- Technical solution definition

- Preliminary design

- Delivery of the first proposal

- Design finishing

- Interfacing with architect and construction companies

- Inspection

- Construction and installation.

Let's take a closer look at each.

1. Interview

The first step is the cognitive interview with the customer: the sales team and the design team come together and interview the customer to get all the basic information required. We talk about the size of the workshop, the quantity and type of workstations, the functions of the different work areas: all this to comprehensively understand the workshop's extraction needs and establish which is the most suitable extraction system.

2. Exhaust gas extraction system study

Once the necessary information has been obtained, the team of designers, guided by the reference PM, meets to identify and define the best solution for the customer's needs: it is decided whether a permanent, underfloor, sliding or stand-alone system is more suitable; how many service units will be needed, how much overall extraction power, etc.

3. Preliminary design

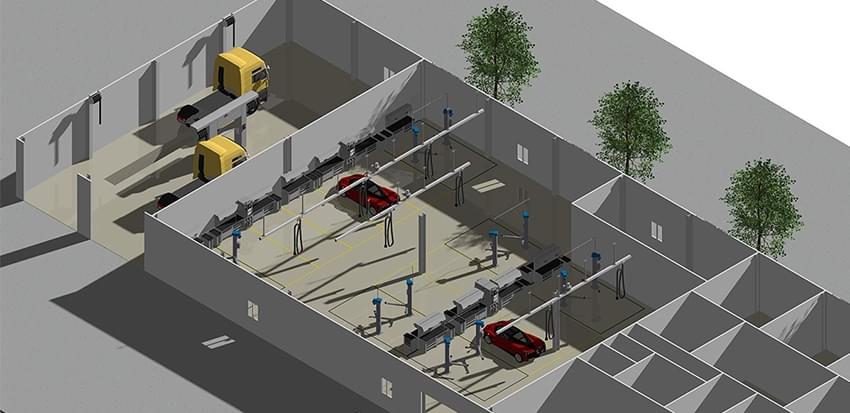

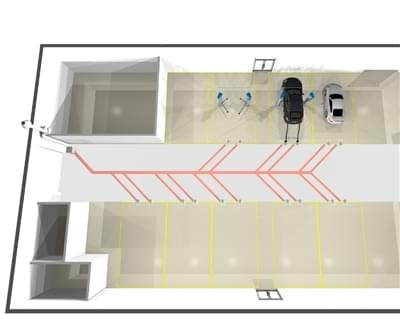

At that point, the first real draft of the extraction system is laid out: having the workshop layout, as a basis, the positions of the different units are set, the paths of the pipes that expel the gases outside the building are drawn, all aligning the customer's wishes and needs with the reference standards.

4. First delivery

The first design is delivered to the customer, possibly accompanied by a 3D rendering that allows him to immediately grasp the final result of the installation of the new exhaust gas extraction systems. In this phase, critical situations or needs not found before may emerge: it is therefore a fundamental phase to make changes if necessary and reach the last step without major obstacles.

5. Design finishing

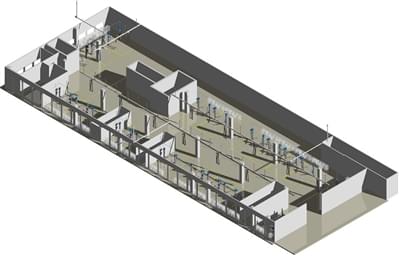

Once any critical issues are settled and the secondary details are specified, the design is finished. The designers then design the final and official version of the extraction system, which faithfully reproduces what will, in fact, be the structure of the new workshop.

6. Interfacing with architect and construction companies

The meeting with the architect who directs the construction work of the Client workshop, and with the companies involved in the construction site, is of vital importance to ensure the perfect integration of the exhaust gas extraction system with the rest of the building.

7. Inspection

Once the comparison between WORKY designers and construction companies has been successfully completed, we carry out a further inspection of the future customer workshop: the objective is to check the list of materials and fixtures, and to ensure that the passage of the pipes and exhaust flue have been made correctly.

8. Construction and installation

When everything has been checked, verified and perfected, we can proceed with the construction of all components - support brackets, arms, ducts, hoses, vents, hose reels, etc. - and finally, install the system.

WORKY extraction system installation is turnkey: from commissioning onwards, our systems run perfectly and are accessible to workshop workers.

Do you want to learn more about our exhaust gas extraction system design? Contact us for a free consultation.