With regard to the technical schools, the courses are held in specialised structures, where students are increasingly given the opportunity to learn how to use the tools of their respective trades, while at the same time, they get to know technologies and systems necessary to keep the air clean. Thanks to WORKY, the most innovative and flexible solutions are at your disposal.

Meanwhile, major car manufacturers are investing in regular training of personnel at their training centres, which are equipped with state-of-the-art equipment.

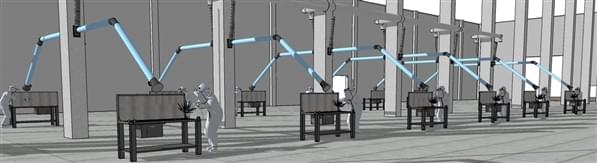

WORKY offers fixed and sliding solutions designed to perfectly adapt to the available space, to the teaching requirements, and to the specific needs of training centres all around the world. Starting by the vast WORKY range of fume extraction products and working side by side with our customers, it is possible to create tailored solutions for every need.

The various WORKY solutions for educational and training centres

WORKY exhaust extraction systems are flexible and can be upgraded over time. For example, two of the best-selling WORKY components that can be included within new systems or implemented on existing systems are listed below.

GRNG nozzle

Nozzle equipped with a rubber cone with a Ø 160 mm intake. Featuring an opening for inserting the emission testing probe, a grip clamp with rubberized ends to prevent it from scratching vehicles’ exhaust pipes.

The nozzle comes standard with a Ø 100 mm stub made from sturdy glass-filled plastic material resistant up to 200°C, equipped with a butterfly damper and a protective grid to prevent any foreign bodies from being sucked into the system.

The GRNG-160100 nozzle is designed for Ø 100 mm flexible hose. The GRNG-16075 and GRNG-160125 nozzles come with painted metal adapters, respectively for Ø 75 mm and Ø 125 mm flexible hose. On the GRNGMC-16075, GRNGMC-160100 and GRNGMC-160125 versions, the nozzles are also equipped with an elbow and handle (which serves also as a further protection to avoid contact with the clamp’s metal parts).

GYNMAG and GYG nozzles

The GYNMAG and GYG models are kits dedicated to dual exhausts.

The GYG kit (which consists of a metal diverter and two completely crush-proof flexible hoses resistant up to 200°C) can be combined with various models of conical and oval nozzles, with or without clamps.

The GYNMAG kit also consists of a metal diverter and two completely crush proof flexible hoses resistant up to 200°C, which are held by self-supporting arms mounted on a trolley base. The nozzles in the GYNMAG kit are conical, while those in the GYNMAG-GON kit are oval. Thanks to their structures, the GYNMAG and GYNMAG-GON nozzles can be positioned next to the vehicles’ mufflers (on cars or motorcycles) without making contact.

Both kits come with a Y diverter with a special groove for quick insertion into the GRNG nozzle.

WORKY also offers solutions for the extraction and filtration of the fumes generated during hands-on welding courses held at institutes of technology.

Mobile welding fume extraction solutions

Mobile extraction and filtration units (also known as stand-alone units) are ideal for work areas that do not require permanent installations.

SB and SBB articulated arms for welding fumes

WORKY is also capable of providing all the support and specialised technical expertise needed to design centralised extraction systems with articulated arms.

For more information on different diameters and lengths, please contact our technical department.

GSAHP high pressure fans

WORKY GSAHP high pressure fans offer excellent performance, while at the same time maintaining low operating power, and can be used for the extraction of both exhaust fumes and welding fumes. The structure is made from sturdy epoxy powder coated sheet steel and features a reverse blade impeller to generate high head values.

WORKY GSAHP high pressure fans offer excellent performance, while at the same time maintaining low operating power, and can be used for the extraction of both exhaust fumes and welding fumes. The structure is made from sturdy epoxy powder coated sheet steel and features a reverse blade impeller to generate high head values.

Electrical panels

The range of accessories in the WORKY catalogue also includes GSQED electrical panels for automatic start/stop of the fan.

An excellent alternative is the GSQEI model that, thanks to the inverter in the electrical panel, optimises the extractor’s performance based on the number of open extraction points, for considerable savings in terms of electricity consumption and heating.

Pocket filters

Finally, the WORKY product range for welding fume extraction systems includes a range of SFT pocket filters (to which the activated carbon filter SFC can be added).

Cartridge filters

The cartridge filters are designed to filter welding fumes without large concentrations of dust. They are capable of filtering and separating the fumes from the suspended dust generated by particularly heavy duty cutting, grinding, or welding operations.

WORKY is at your disposal to design a solution that best meets your customers’ expectations!

Work with us, trust in people able to create a new world around you.